Knee Prosthetic Prototype: Mark I

Goal: Design affordable, customizable lower-limb prosthetics that increases access to devices for amputees in developing countries

I am the co-founder of Koi Prosthetics, a start-up looking to develop an affordable prosthetic knee for amputees in developing countries. According to the World Health Organization, there are 40 million amputees in the developing world, with only 5% having access to a prosthetic device. We have been working with Penta, a non-profit that repurposes used prostheses from the US. We traveled to Vietnam to understand the issues of healthcare and infrastructure for amputees; we also observed social stigmas surrounding such ailment. While there, we learned that the largest bottleneck for prosthetic fittings was the socket, the piece of a prosthetic that directly interfaces with the residual limb. Traditional sockets must be custom-fitted in a weeks-long process that makes it unaffordable for working class amputees. We have been developing an adjustable prosthetic socket and low-cost prosthetic knee that streamlines the fitting process.

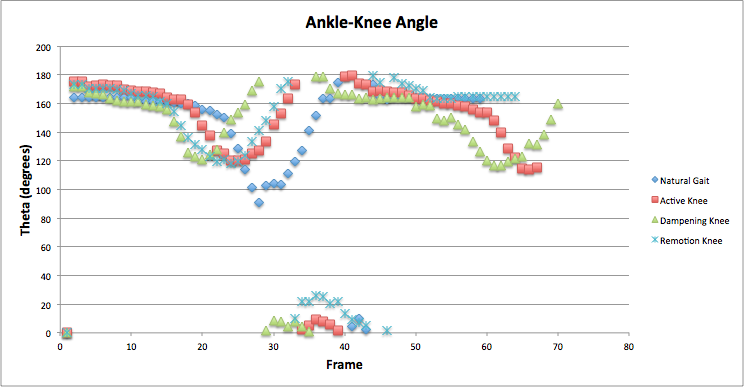

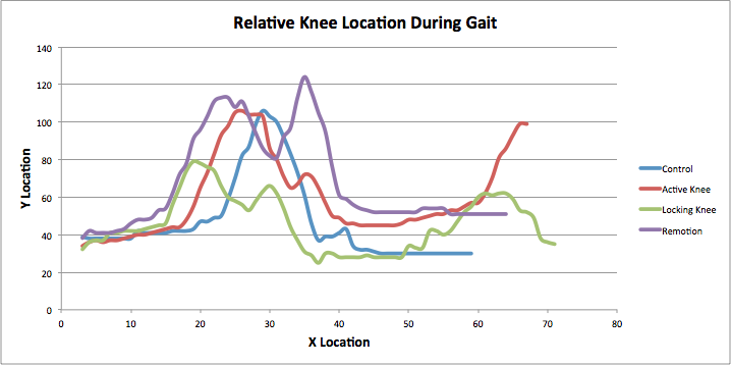

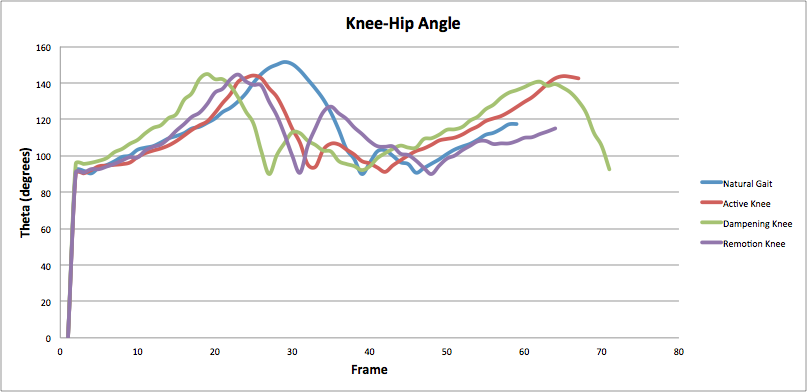

The Prosthetic knee is a product that goes hand-in-hand with the socket. It is low-cost and designed to incorporate an active component. The first iteration (pictured above) is machined from delrin for testing purposes. We created an active mechanism that had severely limited the range of motion of our knee. Thus, the second step was to track the gait cycles of current prosthetic knees on the market. Using Logger Pro, we created a portable motion capture system and test methods, similar to what we used in Vietnam. We created a rig that aligned the tested prosthetic knee with our natural knee to determine their gait cycles.

Using the testing results, we developed an optimized linkage system with an active spring incorporated. The knee looks similar to a natural knee, and is significantly lighter. We are currently running gait tests and will be doing user and failure testing within the year.